Understanding Electromagnetic Shielding

Electromagnetic shielding is a critical aspect of modern technology, protecting electronic devices from electromagnetic interference (EMI). Ensuring the integrity of signals and performance, various electromagnetic shielding materials are employed in different industries to mitigate the effects of EMI. In this article, we will delve deep into the realm of electromagnetic shielding, discussing its importance, various materials used, their applications, and best practices for selection.

What Are Electromagnetic Shielding Materials?

Electromagnetic shielding materials are specially designed substances used to prevent the penetration of electromagnetic fields into sensitive electronic equipment. By blocking, absorbing, or reflecting electromagnetic waves, these materials can mitigate potential disruptions caused by electromagnetic interference. This interference can stem from various sources, such as nearby electronic devices, radio transmissions, and power lines.

The Science Behind Electromagnetic Interference (EMI)

Electromagnetic interference occurs when unwanted electromagnetic signals disrupt the operation of electronic devices. This can lead to malfunction or degradation in performance, affecting various results from data corruption in telecommunication systems to issues in critical healthcare devices. The strength of EMI can vary, necessitating effective shielding strategies tailored to specific needs. Overall, understanding the frequency, wavelength, and amplitude of the interference is essential for designing effective shielding solutions.

Importance of Shielding in Modern Technology

As technology becomes more sophisticated and interconnected, the importance of effective electromagnetic shielding has never been greater. It plays a vital role in protecting sensitive components within devices like smartphones, laptops, and medical instruments. Effective shielding solutions ensure system reliability, compliance with regulations, and ultimately, user satisfaction. Additionally, market demand for heightened data security reinforces the need for robust shielding practices.

Common Types of Electromagnetic Shielding Materials

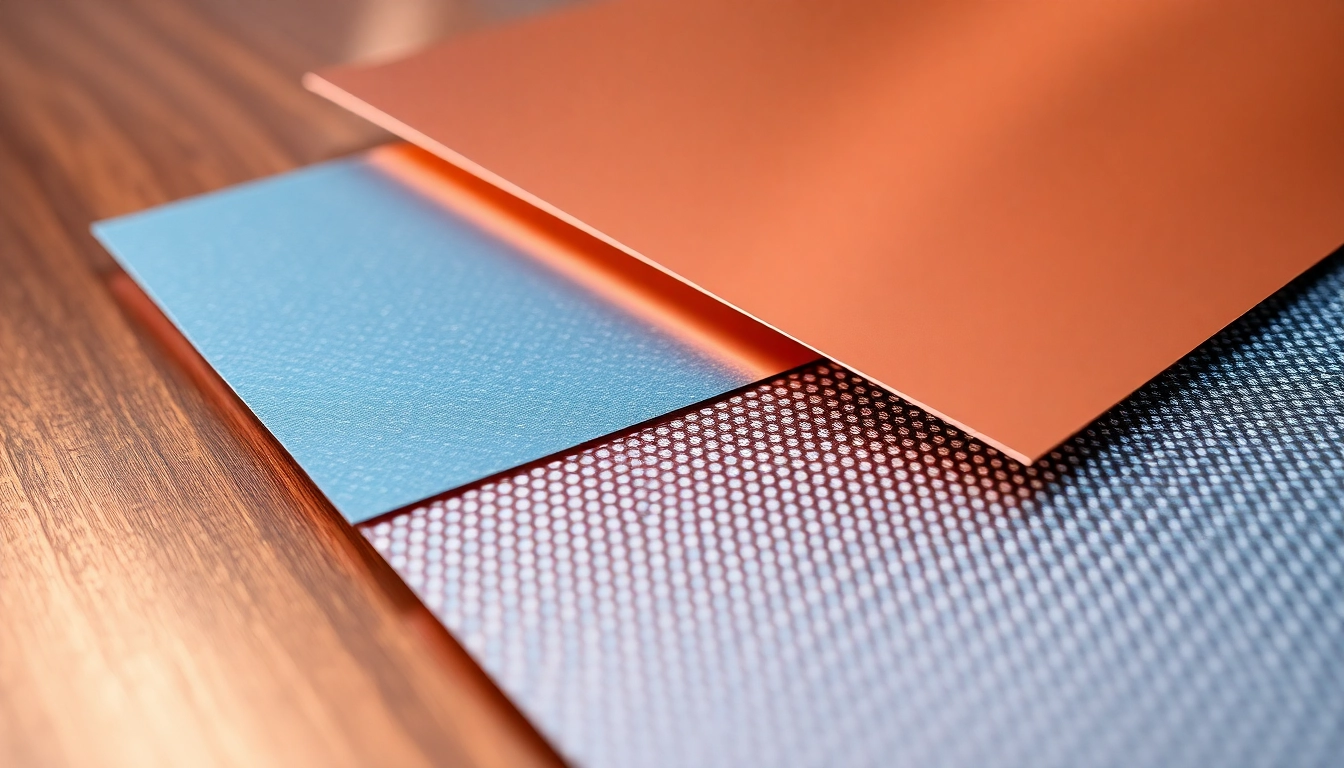

Metals Used for EMI Shielding

Various metals are central to electromagnetic shielding due to their high electrical conductivity and magnetic permeability. Some of the most commonly used metals include:

- Copper: Renowned for its excellent conductivity and effectiveness in attenuating both electric and magnetic fields. Copper is frequently employed in the construction of shielding enclosures.

- Aluminum: Valued for its lightweight properties, aluminum is effective in shielding high-frequency EMI and is less expensive than copper, making it a popular choice for numerous applications.

- Steel: Often utilized in industrial and construction settings, steel provides a sturdy protective layer against EMI and is typically used where durability is essential.

- Nickel: Particularly useful for its corrosion resistance, nickel is often used as a coating material to enhance the shielding effectiveness of other metals.

- Brass: A copper-zinc alloy, brass exhibits good conductivity and is often utilized in connectors and other applications where corrosion resistance is important.

Composite Materials and Their Benefits

Composite materials combine two or more materials to achieve superior performance characteristics not typically obtainable from a single material. In the context of EMI shielding, composites can provide advantages in lightweight design, flexibility, and enhanced shielding effectiveness. Examples include:

- Carbon Nanotube Composites: Known for their outstanding conductivity and strength, carbon nanotube composites are emerging as high-performance materials for EMI shielding.

- Conductive Polymer Composites: These materials demonstrate flexibility and can be processed in various forms, making them suitable for applications requiring conformal coatings.

Conductive Polymers and Innovative Options

Conductive polymers are gaining traction as effective shielding materials due to their versatility and ease of integration into other systems. They can be utilized for surface coatings, where they enhance the electromagnetic shielding capabilities of devices while providing additional benefits like thermal stability and lightweight structures. Innovations in conductive inks and coatings have broadened the application of these materials in consumer electronics and even textiles.

Applications of Electromagnetic Shielding Materials

Shielding in Electronics and Telecommunications

The electronics and telecommunications industries are heavily reliant on electromagnetic shielding to maintain performance and signal integrity. Components within devices such as smartphones, computer systems, and communication antennas often require precision shielding techniques to prevent crosstalk and data loss. Adequate shielding ensures that devices can function effectively in environments filled with competing electromagnetic signals.

Automotive and Aerospace Considerations

With increasing electronic systems in vehicles and aircrafts, the demand for EMI shielding materials in automotive and aerospace applications has surged. Automotive manufacturers are incorporating shielding into dashboard electronics, cruise control systems, and navigation technologies to combat interference from other vehicle functions and sources (e.g., radio frequencies from mobile devices). In aerospace, shielding ensures the functionality of vital systems against electromagnetic interference, crucial for operational integrity during flight.

Healthcare Technology and EMI Shielding

Healthcare technology, particularly in diagnostic and therapeutic devices, faces stringent requirements regarding electromagnetic compatibility. High-precision medical devices, such as MRI machines and CT scanners, depend on effective shielding materials to ensure accurate readings and safety. In addition, wearable health monitoring devices must also employ shielding solutions to protect sensitive electronics from external interference while maintaining user comfort.

Best Practices for Selecting Shielding Materials

Evaluating Material Effectiveness

When selecting shielding materials, it is essential to evaluate the required effectiveness based on the specific application. Consideration should be given to frequency ranges, field strengths, and environmental factors. Shielding effectiveness can be quantified through metrics such as attenuation levels, ensuring that the materials chosen can adequately protect against the specific types of electromagnetic fields encountered in the intended operational environment.

Cost vs. Performance Analysis

Cost is a crucial consideration when selecting electromagnetic shielding materials. While metals like copper offer superior performance, they may not always be the most cost-effective choice. Evaluating trade-offs between performance and price is often essential, especially for large-scale production. Manufacturers might consider hybrid solutions or incorporate less expensive options while still satisfying regulatory requirements and maintaining performance.

Future Trends in Shielding Technologies

Future trends in electromagnetic shielding technologies include advancements in nanotechnology and development of smart materials that can adapt to changing electromagnetic environments. Research is ongoing to harness metamaterials capable of bending electromagnetic waves around objects, enhancing shielding capability without adding weight or bulk to devices. Furthermore, longer-lasting and eco-friendly shielding solutions are witnessing increased demand as sustainability becomes a focal point for consumers and industries alike.

Performance Metrics and Testing Methods

How to Measure Shielding Effectiveness

Shielding effectiveness is usually expressed in decibels (dB), indicating how well a material can reduce electromagnetic waves. Testing usually involves placing the shielding material in an electromagnetic field and measuring the field intensity on either side. Various standards, like MIL-STD-285 and IEEE 299, outline protocols for testing shielding effectiveness, ensuring consistent results across different materials and setups.

Regulatory Standards and Compliance

Compliance with electromagnetic compatibility standards is vital for manufacturers, particularly in industries like telecommunications, automotive, and medical devices. Adhering to regulatory guidelines set forth by organizations such as the Federal Communications Commission (FCC) or the International Electrotechnical Commission (IEC) ensures that products meet necessary performance and safety standards.

Innovative Testing Methods for Quality Assurance

The industry is continuously evolving, with new testing methodologies being developed to provide accurate assessments of electromagnetic shielding materials. Advanced techniques like time-domain reflectometry (TDR) and frequency-domain reflectometry (FDR) offer insights into the properties and performance of materials in real-world applications compared to traditional methods. Enhanced lab capabilities further aid manufacturers in ensuring quality assurance and effective product development.